Products

Wide Application Sachima Production Line Supplier

【MOQ】1 /Sets

【PAY METHOD】WEST UNION L/C T/T CASH

【Warranty Time】 12 Months

【LOADING PORT】Shanghai port/Qingdao port

【Country Of Origin】China

【Application】This production line is used to make sachima, rice candy, sesame seed candy, peanut brittle, caramel treats and other hot snack.

【PAY METHOD】WEST UNION L/C T/T CASH

【Warranty Time】 12 Months

【LOADING PORT】Shanghai port/Qingdao port

【Country Of Origin】China

【Application】This production line is used to make sachima, rice candy, sesame seed candy, peanut brittle, caramel treats and other hot snack.

Features

Technical Data

Message

Features

We are a wide application sachima production line supplier. It adopts advanced technology control system, combined with traditional requirements, and with automatic electrical operating system, so that production can achieve full automation to reduce costs and improve production efficiency.

Application Range of Sachima Production Line Supplier

It is suitable for making sachima, rice candy bar, caramel treats, sesame candy bar, peanut brittle and other foods.

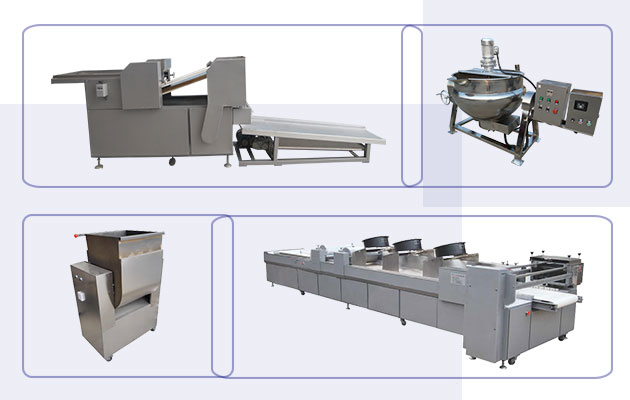

Relevant Machines of Sachima Production Line

This is the four most important machines in the sachima production line, which play different roles in the remanufacturing process.

1. Sachima granules making machine. Mass production of dough granules of the same size as sachima.

2. Sugar cooking pot. Tanning the syrup that binds the raw materials to one piece.

3. Mixing machine. The unique mechanical design allows the sachima granules to be thoroughly mixed with sugar.

4. Automatic making machine. Forced compression rolls provide integration of sachima panels to meet requirements. The air cooler does cool the finished product quickly. The cutting system cuts the sachima panel into sachima of the same size.

The Working Video of Sachima Production Line Supplier

Advantages of Sachima Production Line

Application Range of Sachima Production Line Supplier

It is suitable for making sachima, rice candy bar, caramel treats, sesame candy bar, peanut brittle and other foods.

Relevant Machines of Sachima Production Line

This is the four most important machines in the sachima production line, which play different roles in the remanufacturing process.

1. Sachima granules making machine. Mass production of dough granules of the same size as sachima.

2. Sugar cooking pot. Tanning the syrup that binds the raw materials to one piece.

3. Mixing machine. The unique mechanical design allows the sachima granules to be thoroughly mixed with sugar.

4. Automatic making machine. Forced compression rolls provide integration of sachima panels to meet requirements. The air cooler does cool the finished product quickly. The cutting system cuts the sachima panel into sachima of the same size.

The Working Video of Sachima Production Line Supplier

Advantages of Sachima Production Line

- Achieve automatic and intelligent production, integrate the three processes of mixing, leveling and dicing, which greatly saves production time.

- Standard specification cutting, a large number of cuts at a time, the product is smooth and beautiful, uniform and uniform. Guarantee continuous production.

- With multiple leveling structure, automatic control of cutting speed, automatic feeding, horizontal and vertical automatic feed cutting.

- Provide design solutions for the production line to facilitate your food processing business.

Technical Data

| Name | Size | Capacity | Power |

| Sachima Granules Making Machine | 50-100 kg/h | 1.5 kw | |

| Sugar Cooking Pot | 1320*970*960mm | 100L | |

| Mixing Machine | 800*1400*1020mm | 3-8kg/time | 4.1 kw |

| Automatic Sachima Making Machine | 6000*1200*1200mm | 400-800kg/h | 2.5kw |